Blog

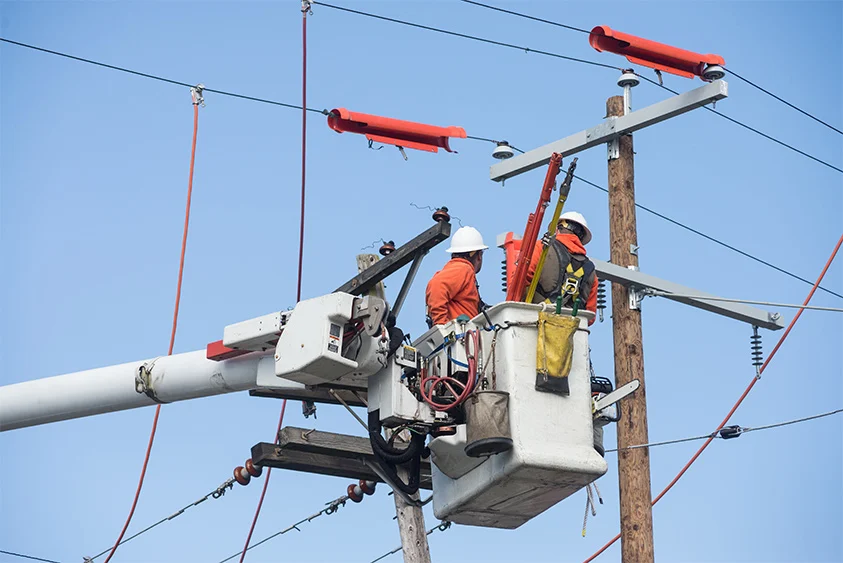

Weatherproofing Strategies for Power Poles in Harsh Climates

Weather elements, such as rain, heat, snow, and wind, affect the durability and performance of power poles. Without effective protection, these elements can cause rust and decay, or weaken installations, compromising safety and power reliability. Weatherproofing allows contractors to optimize poles for installation conditions. Here are a few weatherproofing strategies for power distribution poles in harsh climates:

Protective Coatings

Manufacturers apply specialized coatings that help reduce corrosion and surface damage on steel poles. Hot-dip galvanization is one method and involves adding a layer of zinc on top of the steel to prevent oxidation. Suppliers of power poles dip the structures in molten zinc, which bonds permanently onto the steel, sealing it from moisture and chemical exposure. Galvanization may result in long-term protection. Manufacturers also use powdered and polyurethane coatings to provide hard, moisture-resistant barriers. Surface coatings and finishes reduce UV degradation in dry regions while preventing corrosion in coastal installations. Regular inspection and reapplication may be required for some coatings to maintain year-round performance, especially in areas with heavy rainfall or snow.

Moisture-Resistant Materials

Power distribution poles may be constructed using steel or concrete. Steel is the preferred choice because of its strength and resilience against harsh weather conditions. When galvanized, steel can resist heat, rain, and saltwater conditions, resulting in long-term durability. The material also requires minimal maintenance and offers a lightweight alternative to concrete and wooden poles.

Compacted concrete poles are also weather-resistant and sometimes feature steel reinforcements.

Due to the material’s porosity, concrete poles require regular coating to protect them from moisture and weather damage.

Treated wood poles may be durable but require regular inspection and resealing.

Although the material doesn’t rust, it remains vulnerable to warping, rotting, and pest damage, making steel a more reliable alternative for utility poles.

Joint Sealing

Moisture can enter power distribution poles through joints, welds, and base connections; small gaps form in these areas over time, creating room for moisture intrusion and corrosion from inside. These areas are sometimes hidden, allowing corrosion to spread before it’s noticed; sealing joints and base connections helps prevent such occurrences.

Manufacturers may use special gaskets and moisture barriers for steel poles to protect interior cavities from condensation; pole wraps and sleeves also guard base connections against soil moisture and frost damage. The company should inspect seals and gaskets during routine maintenance and replace them to provide year-round protection against moisture damage. Contractors may also use gravel fills and raised foundations to further reduce direct water contact.

Proactive Maintenance

New pole installations with effective weatherproofing systems can last several years, but over time, they sometimes succumb to natural wear. Ongoing care tracks the deterioration, allowing contractors to intervene before the entire system fails. Routine maintenance involves inspecting the poles for worn-out coating, loose hardware, and foundation issues. Cleaning accumulated dirt and salt helps prevent corrosion from spreading. Check with the utility pole supplier to see if they schedule maintenance services before and after severe weather seasons to address early damage.

- Timely services allow contractors to reapply coatings, tighten fasteners, and replace damaged seals; this protects poles from exposure.

- Modern poles may also be fitted with smart integrations, such as sensors that enable remote monitoring.

- This approach leads to real-time monitoring and timely inspections, and repairs.

- Maintenance records also support consistent follow-up and provide useful data for quality improvements.

- Proactive maintenance factors in local conditions and stressors, allowing utility companies to intervene before poles become exposed.

Find High-Quality Power Poles Today

Power distribution poles should feature high-quality materials that can withstand installation requirements. Poles in coastal and industrial areas require enhanced protection from corrosion, while those in dry regions need ways to address prolonged UV exposure. The poles should be customized to match local climate and environmental forces. Contact a utility systems supplier today to find out more about custom power poles.